[ Automatic Valveless Gravity Filters (Siphon Filters) ]

Advantages

Automatic Valveless Gravity Filters are atmospheric sand filters, often employed as side stream filters in cooling towers circuits for their characteristics:

- No rotating equipment, no PLC, no ON/OFF valves are associated to the system

- The capacity to handle high flowrate of water

- The simple and robust design

- The little maintenance required

The siphon filter principle

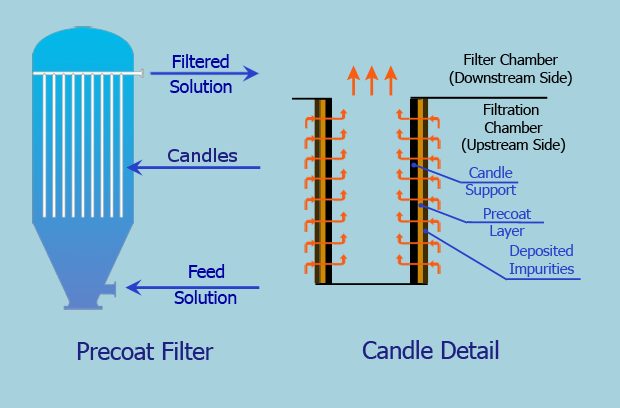

The filter includes a filtration chamber, a backwash water hold-up reservoir overflowing to the treated water header and backwash siphon.

When the pressure drop through one filter reaches the break-through value the siphon is primed. Water contained in the internal reservoir backflows to the waste water channel, backwashing the filtering sand layer. Then the filter returns to normal service.

Unidro solutions

Unidro design include different options for each project optimization:

- Multi-filter systems with distribution tower for flexible management of large flowrate with transportable size equipment

- Double bed filters for minimum footprint

- Site assembly of shop preformed sheets for filters larger than transportation limits

- Concrete fabrication instead of steel shells for cost optimization

- Multiple chamber combined filters for large capacity systems