[ Fluoride Removal ]

The removal of Fluoride from industrial waste

Fluorides removal from waste water streams is a tight task when a concentration below 10 ppm as fluoride ion must be achieved.

In these cases the standard technology (precipitation by lime milk) is not sufficient, being the limiting factor the solubility of calcium fluoride.

Unidro has developed and installed on industrial scale a technology which is able to reduce fluoride concentration to below 2-3 ppm.

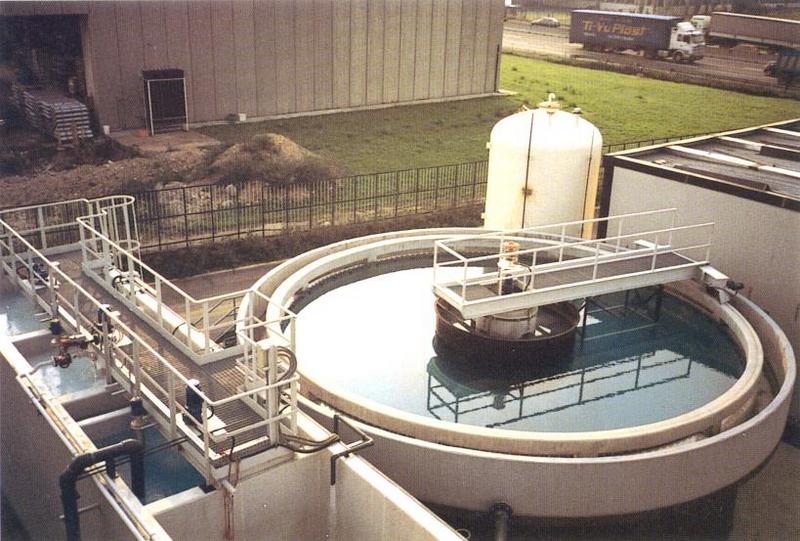

With Acidification, Precipitation, Flocculation, Settling we can get clarified water in the range of 15÷20 ppm F-

The clarifier effluent is released to the filtration step consisting of pressure multi media filters as pretreatment of the final polishing step.

The filtered stream is fed, after pH conditioning, to the Unifluor A filters where the ultimate removal of Fluoride ions down to 3 ppm is finally achieved by an adsorption process.

The activated alumina filters are regenerated periodically by injection of hydrochloric acid and caustic soda after a water backwash. All the waste effluents originated from activated alumina filters regeneration are recycled back to the system upstream sections, so that the only by-product of the entire treatment is the sludge generated at the settling step, to be dehydrated and disposed off.