[ Resin Coalescers ]

Oleophilic resin coalescers are used for the removal of free oil from aqueous streams.

Unidro has a decades-long experience in supplying resin coalescers, and has developed a unique design based on the use of two different kind of oleophilic media (“dual step” coalescer).

The most common application of this technology is the treatment of the potentially contaminated condensates in oil refineries.

Many among the most famous international Oil Companies have successfully installed Unidro coalescers, all around the world.

A Self-regenerating Process

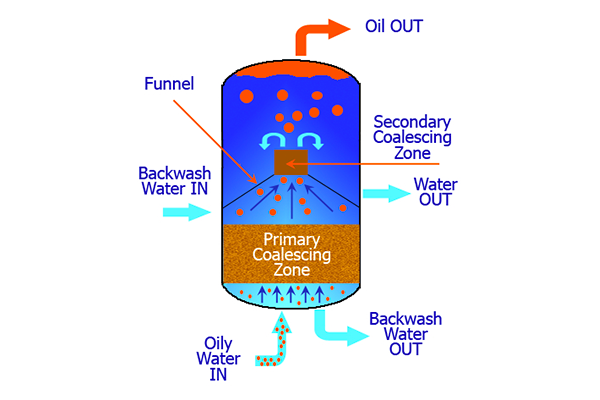

In the resin coalescer, feed water upflows through a sandwich-packed layer of oleophilic resin. Due to the oleophilic properties of the filling media, dispersed oil droplets tend to adhere to the resin beads, thus forming an oily film all around the bead. Once the film grows, it is released by the resin and dragged by the water flow through a second oleophilic media section, where the oil droplets do aggregate to form even larger drops.

At the outlet of the second oleophilic section, water is discharged from a conveniently located outlet nozzle

Application and Performances

Deoiling of contaminated condensate is the typical application of the resin coalescer, which is normally part of a complete treatment unit that includes a pre-filter (installed upstream the coalescer) and an activated carbon filter (installed downstream the coalescer).

Starting from an oil content of several tens of milligrams per liter (up to 100), a typical coalescer performance would reduce the oil concentration down to around 1 ppm. The downstream carbon filter provides final polishing to the condensate, bringing the residual oil content to ppb values. The key added-value of installing the coalescer is the large extension of AC media life before exhaustion, which is proportional to the oil content reduction.

As the coalescer is sensitive to the presence of solids, an upstream pre-filter is normally installed, to protect the oleophilic resin from rust particles that are likely to be present in the condensate.