In chlor-alkali production plants based on membrane electrolysis, the feed sodium chloride (or potassium chloride) brine must be treated to a very high quality i.e. no suspended solids and very low residual hardness is admitted (few ppbs of calcium, magnesium, strontium).

Unidro has a wide record of experiences in designing and supplying tailor made units for each of the main sections of the brine treatment chain: clarification of the saturated brine, filtration of the clarified brine, super-purification of the filtered brine by means of chelate resin towers.

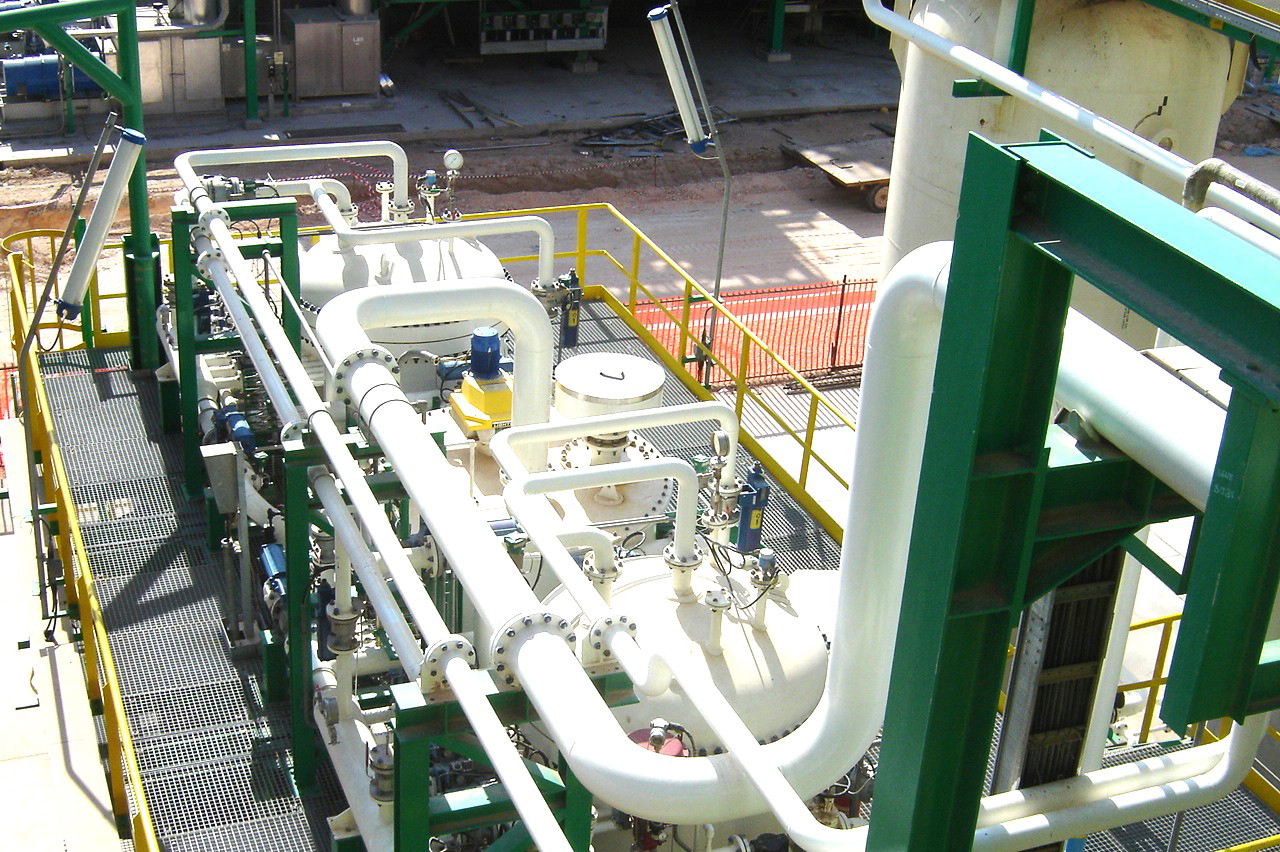

For the clarification of the saturated brine Unidro can propose either a conventional circular-shaped clarifier provided with sludge scraper, or a rectangular settling tank equipped with internals lamella.

Large equipment are normally delivered prefabricated and lined at shop, ready for assembly by bolting only at site.

Rectangular settlers are selected when a very compact system is desired and are delivered as fully pre-fabricated tanks.

Filtration can be accomplished by two steps in series: the first on anthracite filters, to remove the large majority of residual suspended solids; the second on precoat candle filters, to provide a very fine filtration and remove particles larger than 1 micron.

Unidro can provide high-performance anthracite filters, which incorporate a special backwash concept.

Unidro precoat filters based on different type of precoatable candles.

The super-purification of brine is achieved by treating the filtered brine in a chelate resin towers unit.

This unit typically includes three resin columns connected in series, with a “merry-go-round” arrangement.

Regeneration through a complex sequence of steps is fully automatic and operated by Unidro proprietary PLC software.