[ Ultrafiltration ]

Ultrafiltration technology is widely used in the industrial field as well as in municipal applications. In details UltraFiltration is often adopted as a pre-treatment of Reverse Osmosis thanks to its reliability and efficiency. Removal of suspended solids, organics, bacteria and colloids is achieved with very limited waste.

Ultrafiltration treatment can be applied on a very wide range of feed fluids. Unidro experience allows to select proper technology within ultrafiltration and to adapt configuration to specific plant needs.

As a key parameter, suitable operating flux shall be selected according with the feed water type and source.

During operation, UF fibers are automatically cleaned through a compressed air scouring or through a water backwash, depending on the application and on client’s needs.

A schedule for inline chemical cleanings is also foreseen for these elements and optimized in accordance with the operating parameters of each installation.

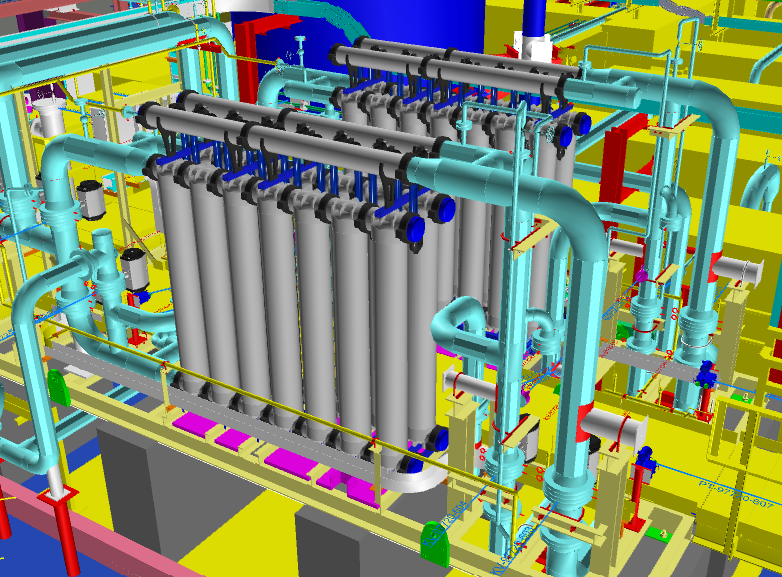

- Footprint: comparing with traditional pretreatment allows footprint saving, due to very compact installation.

- Adaptability: we select the most appropriate design with reference to process requirements and flowrate range.

- Modularity: our systems may be extended by adding modules to increase the water treatment capacity.

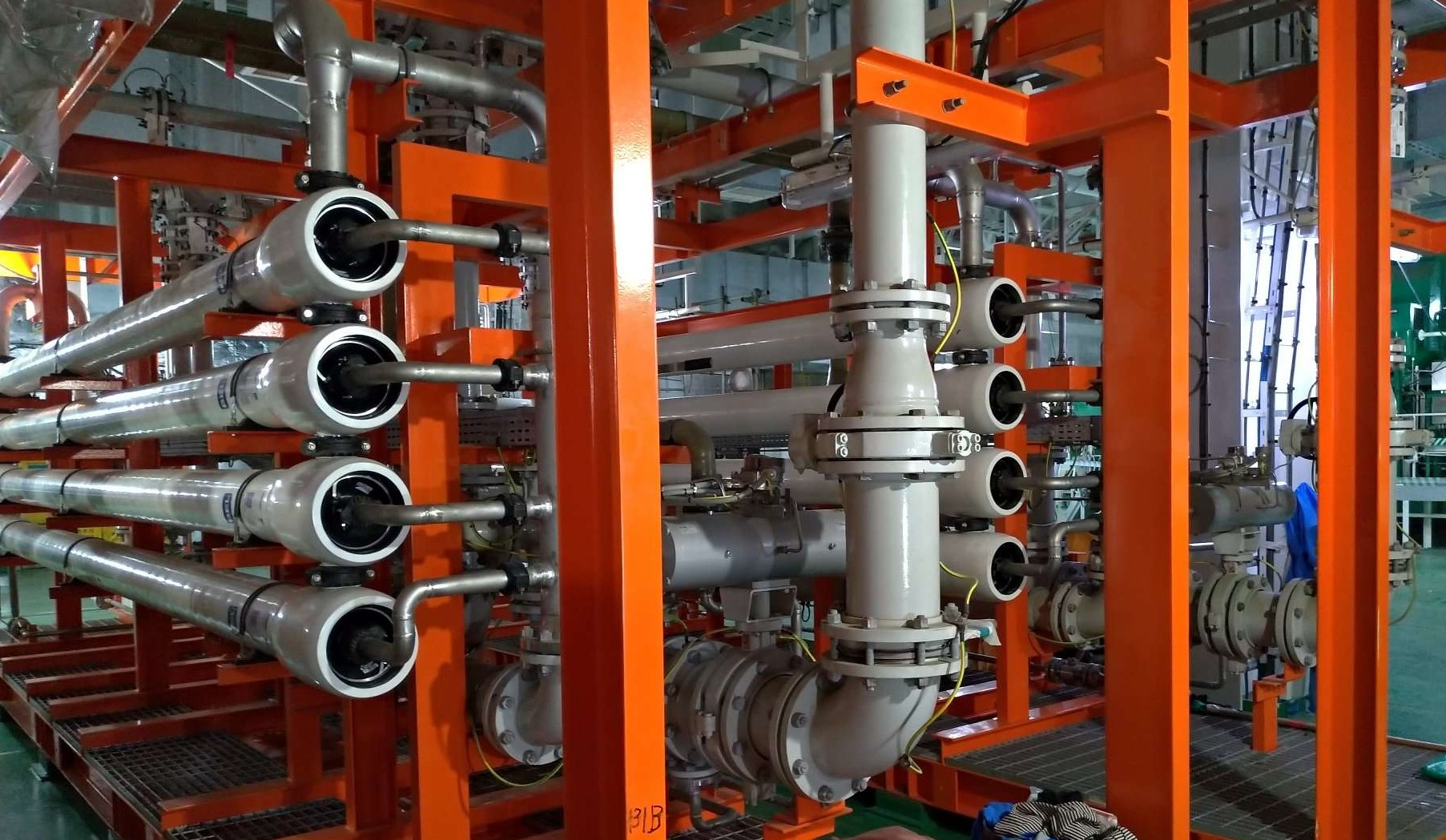

Unidro has experience in design, commissioning and start-up of different Ultrafiltration technologies:

- Pressurized UF / submerged UF

- Hollow fiber – Single capillary / Multi-bore

- Material: PES / PVDF (TIPS or NIPS)

- High pressure / low pressure

- Inside – Outside filtration / vice-versa

- Water backwash / Air scouring

- Vertical standalone module / Horizontal multi-membrane pressure vessel

- Dead-end / Crossflow operation